Toshu Super Blue Steel, Gyuto Chef Knife, 240mm/9.45in

$329.32

Chef knives made by Toshu have all of five features that finest kitchen knives must have. Toshu makes knives using traditional Japanese swordsmiths’ techniques, “Hizukuri Forging” and “Edo-Togi grind”.

Toshu Super Blue Steel chef’s knives are ones made of the highest quality steel. Although they look like ordinal kitchen knives at first glance, their cutting performance is second to none. To begin with, blue steels (also called "Aogami") are the strongest material among steels in the market. Blue steels are increased wear resistance and stickiness compared to ordinal white steel, by adding chromium and tungsten. Their rockwell hardness (HRC) is over 60 (very hard). Super blue steel surpasses the performance of blue steels. It is harder (cut sharper), stickier (hard to chip in a blade), and more wear resistance. In addition, super blue steel overcomes a defect, easy to chip, of blue steel. Furthermore, Toshu Super Blue Steel knives are made to be easier to use by three layer structure of the blade; super blue steel core is sandwiched by stable steel materials.Full lineup of Toshu Super Blue Steel knives

Gyuto knife is the Japanese chef’s knife with a Western style curved blade so that it can smoothly move back and forth to chop meat quickly. This can also use for cutting fish and vegetables.

The Gyuto is the one of the most versatile knife best for all kinds of professional chefs.

Hizukuri Forging

This forging method is traditionally used for Japanese sword making since Samurai era. Heating material up to 1,000 degrees Celsius, craftsmen hammer the material repeatedly to make it hard and to form the shape of blade.

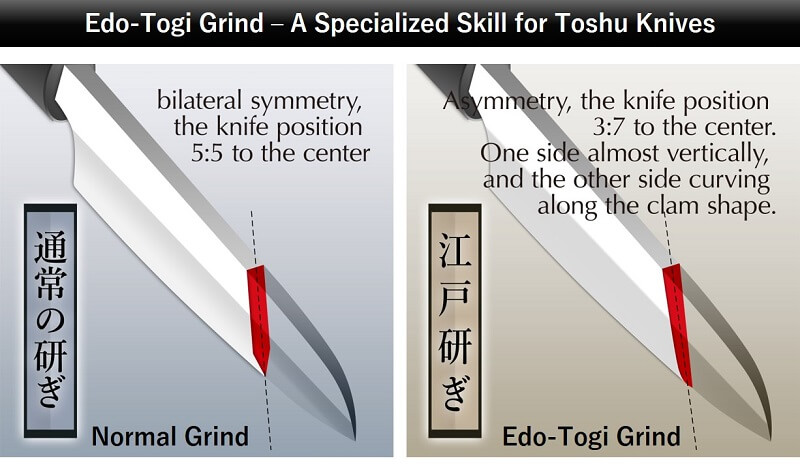

Edo-Togi Grind

This grinding method can be done by limited artisans because it requires high level skills. Each side of the blade is sharpen asymmetrically in this method; one side is sharpen almost vertical, whilst the other side is to form clam-like curving shape; and edge of the blade should be placed at the 3:7 position to the center. This technique gives tremendous advantages to the knives as described below.

Making Process of Toshu Chef Knives

Making knives with these traditional techniques by hands requires high level skills and takes longer time than making by machines. However, every step of the making process has important meaning and effects which has been elaborated by past artisans. Thanks to the complicated 60 steps by experienced craftsmen, Toshu knives has all of five features that finest kitchen knives must have. They are 1)hardness which affects cutting quality and makes hard to get chipped, 2)flexibility for good cutting quality, 3)abrasion resistance to keep cutting quality for longer time, 4)fatigue resistance which keeps cutting power for longer time, and 5)corrosion resistance. Once you use a Toshu knife, you’ll instantly feel the difference between our product and ordinary knives which are die cut from metal plate and mass-manufactured by machines.

In addition, Toshu knives prevent odors of the steel from spreading to foods, and fat of foods are hard to stick on the blades. Many professional chefs have used our knives regularly.

Furthermore, well-made knives are easy to be repaired. Sending back your knife to us, Toshu craftsmen are happy to repair and restore it as if it’s new. It is only possible for the handmade knives, therefore our knives can be used for many years to come.