The Making Process of Japanese Knives

The Japanese Knife making starts from “forging process” to form steel materials to the shape of knife. The forged knife then proceeds to “grinding process” to make it sharp, followed by “handle attachment” and “inscription”.

The knife making in Sakai takes polyethism. Due to its complexity, entire making process of knife is divided into several sub-processes, and each sub-process is done by specialized artisans. This has advantages that 1) artisans can have higher skills for his specialized sub-process than those who have to learn entire process, and 2) artisans of a sub-process check quality of previous sub-process, which enables double-check of products and plays an important role to avoid producing knives for inferior quality.

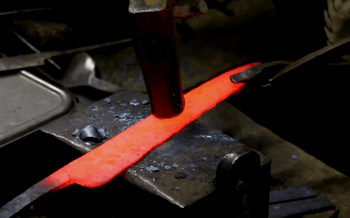

1. FORGING PROCESS

Grinding

Well cut knife should have perfectly straight spine, from tip to handle.

Due to rough grinding process with grinder, knife would have heated, and it would result in causing a little bit distortion. Artisans sharpen the knife, as fixing distortion by sparpening machine at the same time. The knife would have enough cutting quality after this process.

Buffing

Using buff, polishing agent on multifold rounded cloths in layers, artisans put a good shine on the knife by polishing. Finishing up with paper buff named “flap wheel” to give it sophisticated beauty like Japanese swords.

2. GRINDING PROCESS

Rough Grinding

Using grinder, rasp off unnecessary part of knife and make thickness of the knife even.

Grinding

Well cut knife should have perfectly straight spine, from tip to handle.

Due to rough grinding process with grinder, knife would have heated, and it would result in causing a little bit distortion. Artisans sharpen the knife, as fixing distortion by sparpening machine at the same time. The knife would have enough cutting quality after this process.

Buffing

Using buff, polishing agent on multifold rounded cloths in layers, artisans put a good shine on the knife by polishing. Finishing up with paper buff named “flap wheel” to give it sophisticated beauty like Japanese swords.

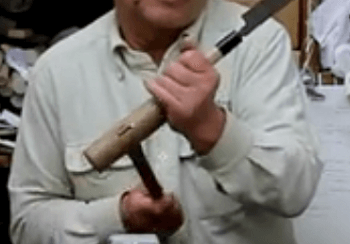

3. HANDLE ATTACHMENT

Handle Attachment

For some types of knives, handle is fixed to a knife with rivets, followed by waxing to give it shine.

For the other types of knives, heating a knife by burner and pushing it into a handle by mallet.

Inspection and Encasement

After a final quality check, the knife is encased in packing materials and a box.

Related Pages

CONTENTS

PRODUCT CATEGORIES

Santoku Knife

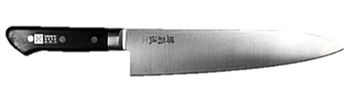

Gyuto Knife

Petit Knife

Deba Knife

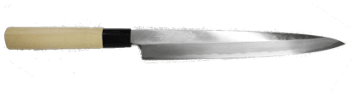

Yanagiba Knife