Japanese Knife

Edo-Togi: Special Sharpening Technique Inherited by Few Craftsmen

There is a special sharpening technique called “Edo-togi grind”.

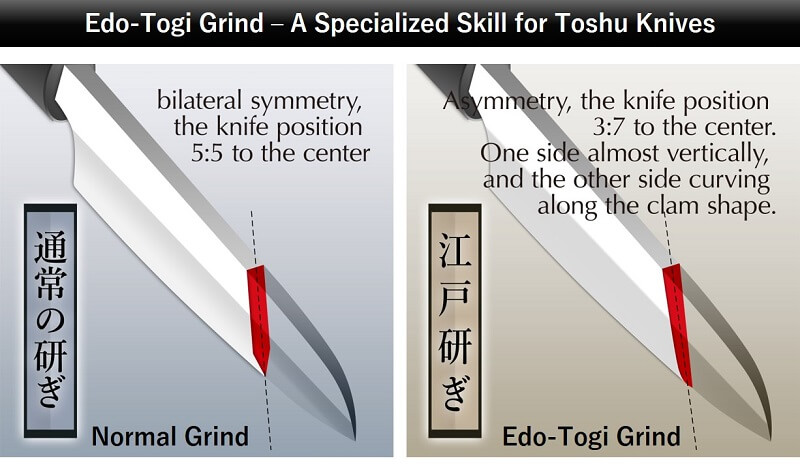

In Edo-togi grind, each side of the blade is sharpen asymmetrically. One side is sharpen almost vertical, and another side is to form clam-like curving shape. The edge of the blade should be placed at the 3:7 position to the center. This grinding method is precious because only a few artisans in Japan are capable of doing the high level grinding.

Please look how sharp a knife by Edo-togi grind is.

There, a man is cutting a newspaper by a knife finished by Edo-togi grind.

This cutting method is called “scooping” cut by which a paper on a flat surface is cut.

This can be done this smooth only by extremely sharp knives. (Please try this with your knife!)

In this post, let’s see how this extremely sharp knife is made.

Five Steps of Japanese Handmade Knife Making Process

1. Forging Metal Material

The word “swordsmiths” originates the beating heat iron. Forging is a step to strengthen steel by hammering heated iron of nearly 1,000 degrees Celsius. Generally, knives are made by more than one metal materials; they are hammered to be welded so that it becomes strong and hard enough. Therefore, this step is fundamental for the strength and hardness of the knife blade.

2. Quenching and Tempering

Generally, sharper edges are easier to be chipped. Likewise, every metal material has advantage and disadvantages. Easier to handle and sharpening, but harder for acid and get easier to rust; long lasting sharpness but hard to do sharpening, and so on. In addition to the characteristics of a material, quenching and tempering derives its characteristics and destines its metallic characters. In this step, craftsman aims to derive and complement corrosion resistance, abrasion resistance, hardness and durability from raw materials.

3. Welding and Molding

Followed by preforming forged materials, craftsman forms shape of knife blades with waterstones. Then, some parts (e.g. a metal part between blade and handle) are welded after the forming. By this step, shape of the blade is completely made.

4. Grinding and Sharpening

Even the knife shape is completed by this step, it’s still dull until it’d be sharpened. Although sharpening is done by experienced craftsmen, cutting quality depends on how well the blade is made in the previous steps. Well made blades are easier to grind and sharpen, craftsmen say.

For high grade Toshu knives, highly skilled sharpening craftsmen perform Edo-togi grind to made asymmetrical grind to place center of the edge at the 3:7 position to the center. 3-side (or 7:3) should be sharp like vertical and 7-side should be shaped to form clam-like curving shape. Edo-togi craftsmen say they use 5 kinds of waterstones and arrange by .1 mm-base. Machines can never make such a sensitive work. It’s a world of artisan’s feeling.

5. Handle Attachment

Last step of knife making process is to attach handles, followed by waxing to give it shine. Toshu high grade knives require more than 60 sub steps to complete one knife. Compared to mass-made knives by machine which is diecut from metal plate and formed shapes, Toshu knives cannot make a lot due to complicated processes and limited number of craftsmen. However, Toshu knife’s cutting quality is second to none thanks to the traditional craftsmanship since hundreds of years.

Why Edo-togi Grind Cut That Sharp?

One of the secrets is its edge angle.

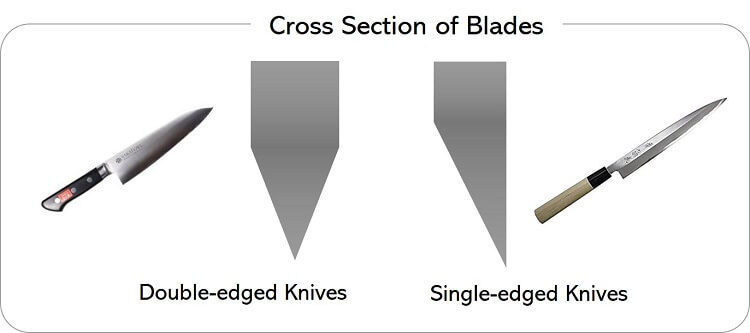

Generally, single-edged Japanese knives cut better than double-edged Western knives. This is because, structurally, single-edged blade can be sharper in its angle.

In Edo-togi grind, blade can be as sharp as single-edged knives by vertically sharpening 3-side of 7:3 edge.

However, the sharper edge of single-edge Japanese knives has a disadvantage. Due to its sharpness, it gets chip in a blade or tends to be worn out easily.

Therefore, Edo-togi grind came up with the idea to form 7-side of 7:3 blade clam-like shape. Thanks to its clam-like shape, Edo-togi ground blade became difficult to get chip and to become dull. Only con of this unique double-edge structure is difficult to make. It requires higher techniques to craftsmen.

Edo-togi Grind Requires Experience, intuition and…?

What is special about Edo-togi grind is that craftsmen make the asymmetric blades all by hands based on their experiences and intuitions. By sharpening, they decenter blades and form vertically sharp edge and clam-like shape edge at the same time.  To enable this unique shape of the blades, knife making steps, especially welding and molding step, are specialized to some extent. Thus, the base material of the blade is also specialized to Edo-togi grind, which enables to make Edo-togi grind easier not only for craftsmen but also users. In other words, it keeps its cutting quality when you sharpen Edo-togi grind knives by yourself.

To enable this unique shape of the blades, knife making steps, especially welding and molding step, are specialized to some extent. Thus, the base material of the blade is also specialized to Edo-togi grind, which enables to make Edo-togi grind easier not only for craftsmen but also users. In other words, it keeps its cutting quality when you sharpen Edo-togi grind knives by yourself.

In case you come to be unsatisfactory with its cutting performance after you sharpen many times, then send it back to craftsmen, and they’ll recover its performance to the original state. Thanks to its high quality basement/materials, Toshu knives can recover shape and cutting performance by craftsmen.

In Conclusion

Hope you could understand details of Edo-togi grind.

Although Edo-togi grind is a special technique mastered by a few craftsmen, their products are practical and for daily usages. Please use their knives for your everyday cooking and enjoy highest cutting performance of Toshu knives. It easily keeps its excellent cutting power by your sharpening (or you can bring it to sharpening stores near your location). Also, please remember that you can send it back to Toshu to recover whenever you want to!

If you’re interested, you can purchase Edo-togi grind knives in our shop.

It’s certainly pricy knives, but you’ll understand instantly that Toshu knives are completely different from any knives you’ve used.

Author - Hiro

Lived in Kyoto in school days, I was impressed by profundity of history and tradition of the city. Had a job to join the three major festivals of Kyoto: Aoi, Jidai and Gion festivals. Love Kyoto and Japanese culture.

Manager of OrientalSouls.com, selling items of Japanese culture, tradition and craftsmanship. I'll introduce interesting information about Japan!

About Orientalsouls.com

Learn and Buy Japanese Craftsmanship, Tradition & Culture

OrientalSoul.com is the online shop where you can buy traditional crafts of Japan.

We only sell selected authentic products in which true spirits of Japanese craftsmanship exist.

You may be able to find similar products in other shops for lower prices. However, we sell products based on fair prices that worth labor and value of experienced craftsmen.

In addition, we introduce stories about product history, how a product is made, what makes it different from others, and how the product enriches your life!