Japanese Knife, Japanese Traditional Crafts

Space Age Technology Cutting Your Steak: State of the Art Echizen Cutlery

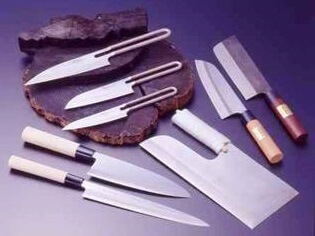

Echizen uchi-hamono are the famous bladed utensils from Echizen city known for their double-layered (ni-mai kasane) forging and diagonal splaying (mawashi haganetsuke) methods with which they are hand crafted.

The double-layered (ni-mai kasane) method used while making Echizen blades involves stacking, hammering, and forging two blades at once. By doubling the thickness of the blade, later strikes from the hammer result a strengthened and elongated blade. Finally, due to its thickness during forging, this double-layered method ensures the steel retains its heat throughout the process, meaning that the steel does not need to be returned as often to the abusive, imperfection-causing heat of the furnaces.

The diagonal splaying (mawashi haganetsuke) method has artisans hit the steel in diagonal pattern, beginning with its corner while working their way across its entire face. This results in a thinner, durable, and more easily sharpened curved blade for use as a sickle. These methods, unique to the Echizen cutlery bladesmithing craft, produce lightweight, thin utensils with efficient and long lasting cutting ability.

(Image: city.echizen.lg.jp)

The Birth and Legacy of Echizen Cutlery: History of the Blade, Past and Present

In 1337, while searching for the perfect region in which to establish a bladesmithing practice, Kyoto swordmaker Chiyozuru Kuniyasu discovered the fine clays and pristine waters of what would later become Echizen city in present day Fukui prefecture, Japan. Here he began his blacksmithing alongside the many farmers who lived nearby. It was Chiyozuru’s work producing sickles for his hardworking neighbours that is said to have begun the Echizen uchi-hamono tradition. Using ancient Japanese forging techniques different from the casting mold method of melting and cooling of steel, the Echizen methods allow free and masterful shaping of each unique utensil. Thus, in addition to razor sharp blades, the Echizen forges produced pruning shears, sickles, and other useful farming tools.

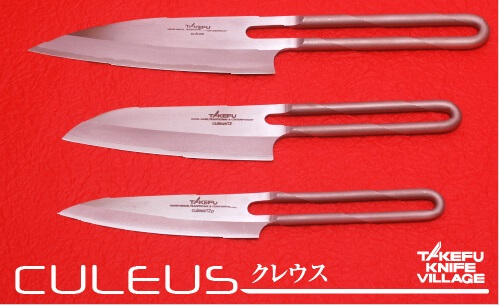

(Image: Rakuten Shop)

Thereafter, the double-layered forging and diagonal splaying methods were developed and perfected over centuries and into the present. Today, they are in continued use and improvement in the Echizen workshops. Recently, through rebranding efforts and the impressive designs of new, original models, the Echizen smithies have continued this legacy of innovation and production.

The Popular Echizen Culeus Knife

Combining the traditional Echizen cutlery forging techniques with the touch of famous industrial designer Kazuo Kawasaki, the radical Culeus kitchen knife is a modern take on an ancient knife making tradition. Since its revealing, the Culeus kitchen knife has garnered attention for its extraordinary and useful cutting performance and impressive, intelligent design.

With a combined blade and handle design, the Culeus knife uses its consolidated body to address the perceived weaknesses of most Japanese knife: Namely an attached, wooden handle attracting filth and rust. Moreover, through its high-grade, triple layered stainless steel called V-700, the Culeus knife represents a new generation of easy to obtain knifemaking material with unprecedented levels of rust resistance. With an unparalleled cutting ability achieved via this combination of traditional forging methods and state of the art materials, the V-700 stainless steel of the Culeus knife achieves a Vickers Hardness specification of 700, and Rockwell Hardness of 60-62.

The Steak Knife of World-Class Chefs: Ryusen Cutlery

(Image: sunchi)

Next, allow me to introduce Ryusen Cutlery of Echizen city, Fukui Prefecture’s steak knives. This knife was designed on the request of then head-chef of the exclusive Hoshino Resort at the Hotel Bleston Court in Karuizawa, Nagano Prefecture, Hamada Tsuneyuki in his quest for the best cutting steak knife to put to use at his newest high-end dining hall.

Ryusen Cutlery conducted preliminary research by gathering steak knives from around the world. At this time, steak knives were typically serrated, using their jagged edge to dig and tear the meat with friction. Ryusen Cutlery then considered reusing their tried and tested materials, conducting further research sharpening soft and hard steels in variously arranged layers. It was precisely this combination of various materials they found produced a file-like edge which in turn cut food not on contact but upon but the slightest, gentlest pull. After creating a single prototype, a further two years of research were invested into making what Ryusen Cutlery call “both the sharpest and safest” steak knife developed. The Ryusen Cutlery steak knife was later put to use by the Japanese team at an international culinary competition. It is said that more than half of the judges at the event went home with Ryusen Knives that night. This helped the massive and sudden spread of the Ryusen Cutlery name around the globe.

(Image: sunchi)

Today, since being widely adopted in France and Italy, the Ryusen Cutlery steak knife has spread to the United States, Germany, Holland, Hong Kong, as well as number of other culinary capitals around the globe, where it has become a beloved companion at the dinner table. However, with production of this famous steak knife limited to only 150 per month, the current waitlist is said to be a lengthy four years.

Echizen Cutlery: Classic Techniques with a Space Aged Applications

As we have seen, the modern application of Echizen uchi-hamono traditions has already produced a handful of innovative products. With widespread recognition of the artisans and modern engineers working in and with Echizen city workshops, the world anxiously waits to see what these engineers and artisans might come up with next. Meanwhile, people dining at tables and working in kitchens everywhere continue to enjoy the easy cutting, durable knives produced by the fires of Echizen furnaces.

Author - Jay

In my spare time I enjoy watching baseball, tasting local cuisine, and exploring by road and rail. Having lived in several cities around the world, I have an appreciation for local as well as international histories and cultures. Excited by cultural and social exchange, it is my hope that this blog will help promote an interest in Japanese traditional wares and practises by introducing you to their history and meanings.

About Orientalsouls.com

Learn and Buy Japanese Craftsmanship, Tradition & Culture

OrientalSoul.com is the online shop where you can buy traditional crafts of Japan.

We only sell selected authentic products in which true spirits of Japanese craftsmanship exist.

You may be able to find similar products in other shops for lower prices. However, we sell products based on fair prices that worth labor and value of experienced craftsmen.

In addition, we introduce stories about product history, how a product is made, what makes it different from others, and how the product enriches your life!